Structural Design

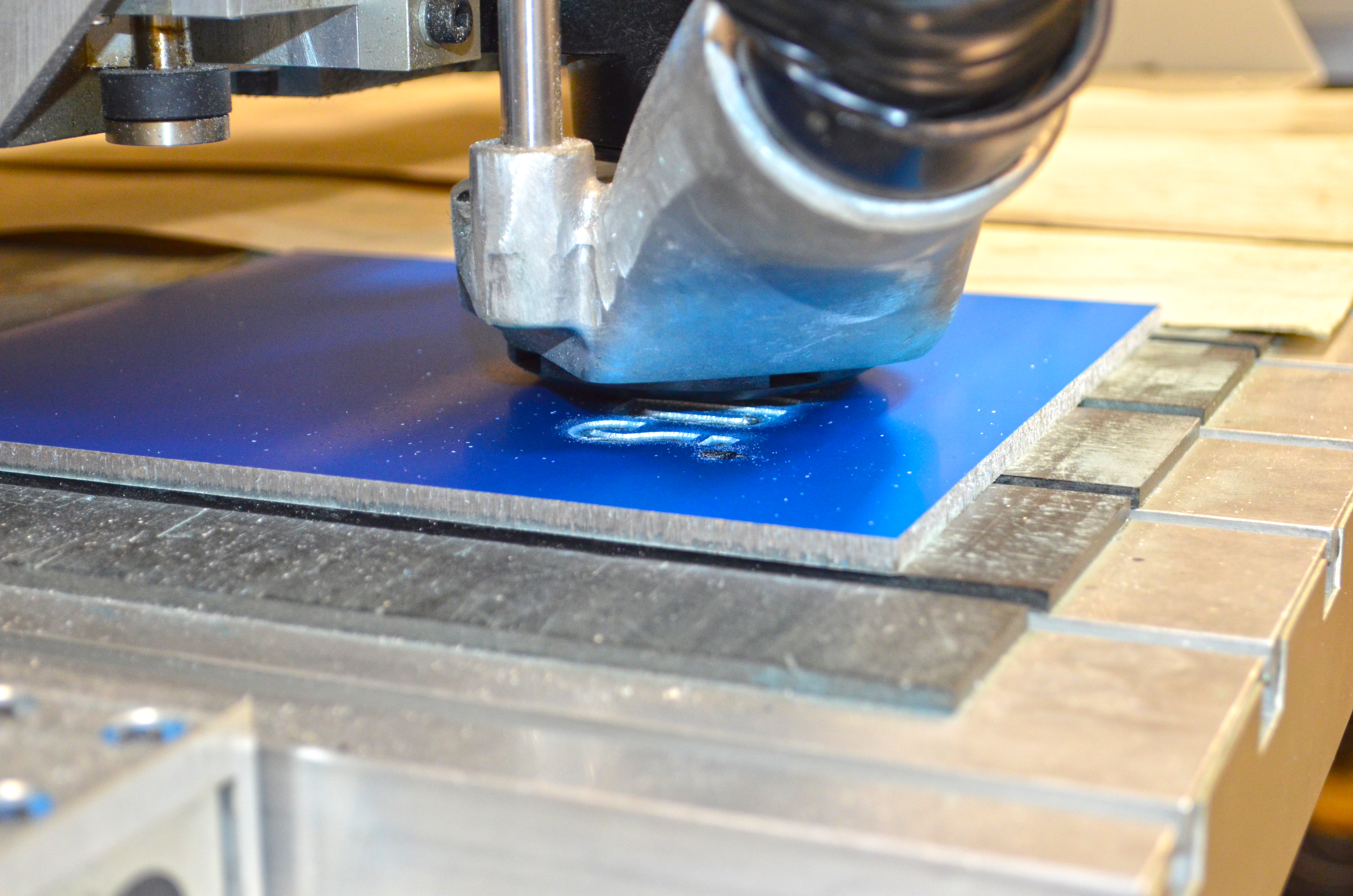

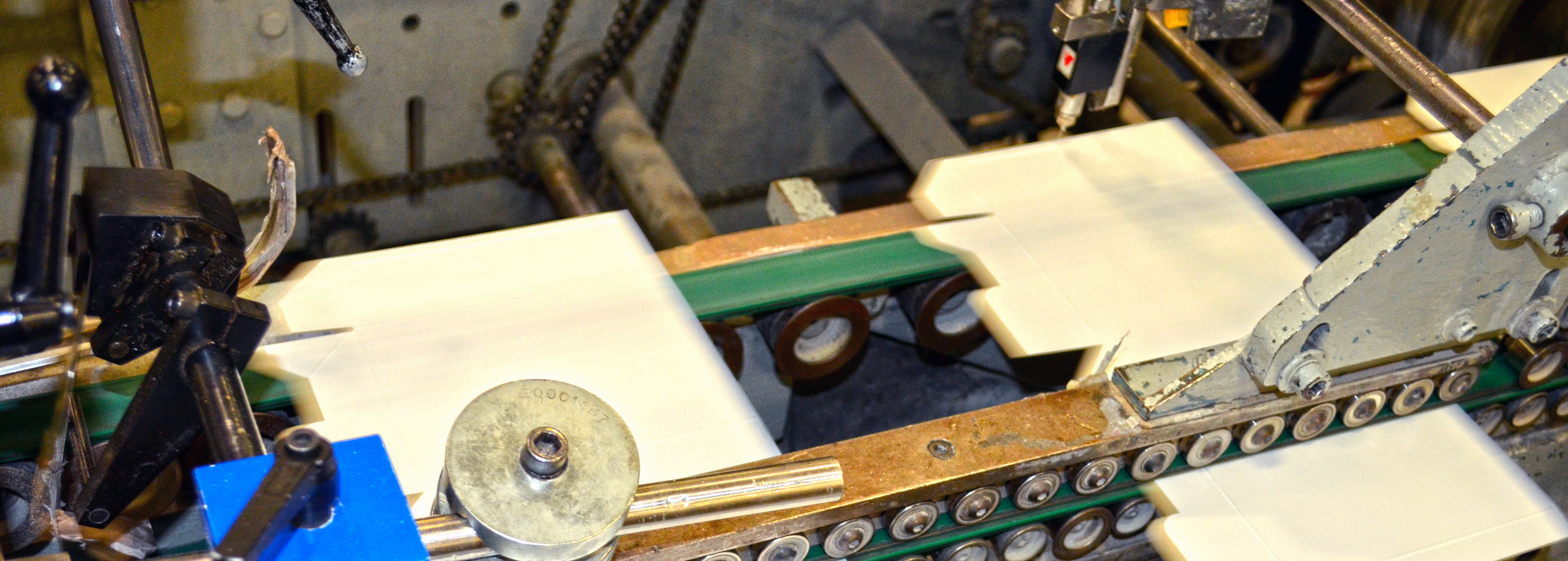

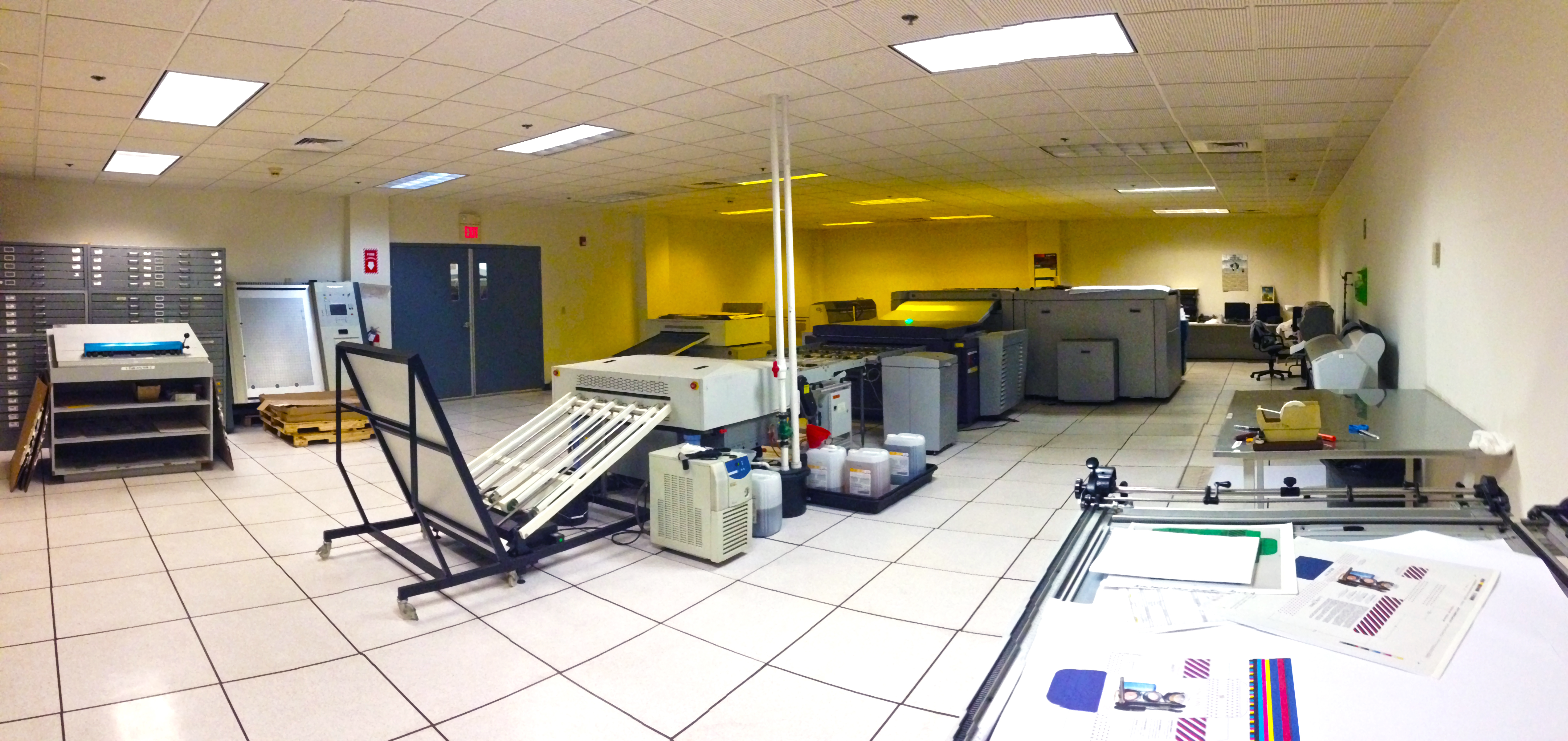

Color Optics uses state-of-the-art technology, including CAD/CAM software and advanced sample-making technology. Using this technology, Color Optics creates a Color Accurate Prototype (CAP), an exact replica of your packaging, that is die-cut and glued to its final dimensions using the actual substrate for the production run. This exact prototype expedites internal reviews and approvals, accelerates the production of advertising, promotional materials and displays, and enables clients to preview the product/packaging with retailers.